S5 stock manifold, External dump

#1

Here's a sneak peak at this for now. I have been seeing here, and other places, where people want to fix the whole boost creep, and boost dropping off before peak RPM. One way is to get an upgraded Garrett internal gate that is very similar to our stock wastegates, and port the wastegate areas on the turbine housing. This works well for a lightly modded car, but some still need more. Especially if the motor is ported, running higher compression, or runnning a hybrid turbo.

Now it has been done a few times on the much larger S4 manifold. But with the very small compact S5 manifold, and divided runners, making an external dump far more complicated. A few people have also kept the stock wastegate area but separated the down pipe area and wastegate area for an external dump. This still poses a problem with releasing enough exhaust pressure through the holes in the turbine housing. Making creep and drop off less noticeable, but not getting rid of it.

Here is what i am going to do to fix the problem. A one inch hole in each runner, meeting at one point with a 38mm external wastegate.

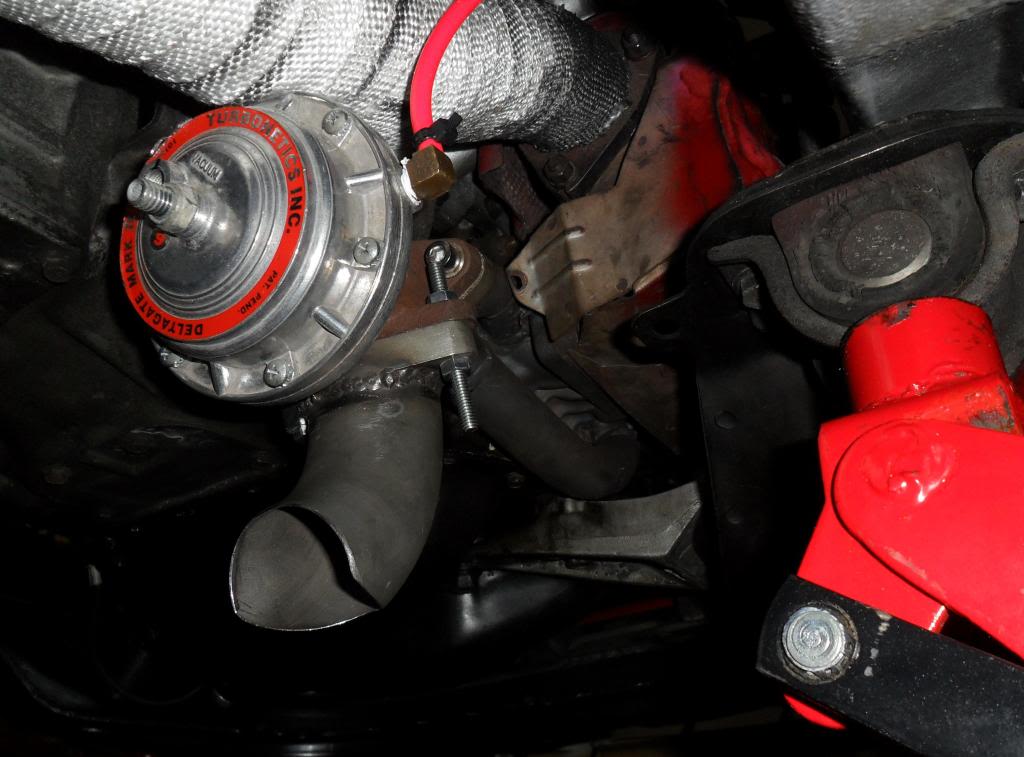

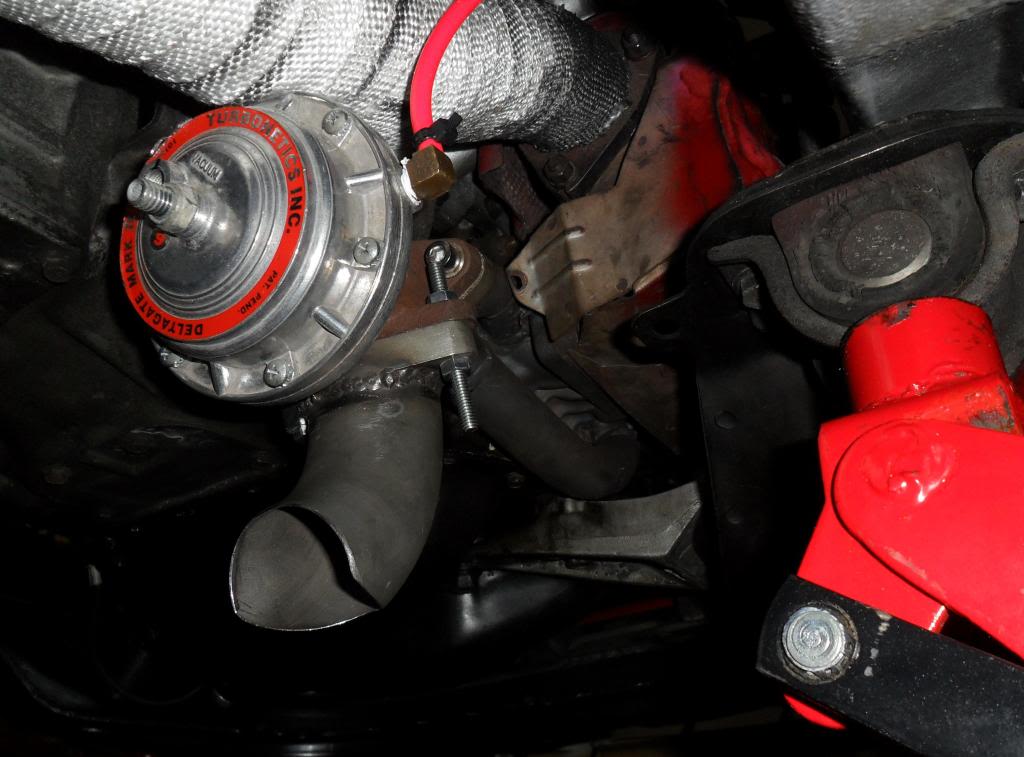

Pics do much better than words.

(I'll update after it's all welded up and finished, I got side tracked with another project and didn't get t finish)

Holes were done with a bridgeport mill. Now I know not many people here will have access to a machine like that. but its not hard to drill a hole with a hand drill and port it out with a die grinder.

Got some pipe and turned it down slightly in a lathe to fit very snuggly in the holes. I'm all about tight fits,

Cut some pipe and mocked it up. A little trimming and grinding, and this will all fit nicely. There's actually a pretty good amount of room below the manifold to come up with your own design. Just take some measurements and get to cutting!

Now it has been done a few times on the much larger S4 manifold. But with the very small compact S5 manifold, and divided runners, making an external dump far more complicated. A few people have also kept the stock wastegate area but separated the down pipe area and wastegate area for an external dump. This still poses a problem with releasing enough exhaust pressure through the holes in the turbine housing. Making creep and drop off less noticeable, but not getting rid of it.

Here is what i am going to do to fix the problem. A one inch hole in each runner, meeting at one point with a 38mm external wastegate.

Pics do much better than words.

(I'll update after it's all welded up and finished, I got side tracked with another project and didn't get t finish)

Holes were done with a bridgeport mill. Now I know not many people here will have access to a machine like that. but its not hard to drill a hole with a hand drill and port it out with a die grinder.

Got some pipe and turned it down slightly in a lathe to fit very snuggly in the holes. I'm all about tight fits,

Cut some pipe and mocked it up. A little trimming and grinding, and this will all fit nicely. There's actually a pretty good amount of room below the manifold to come up with your own design. Just take some measurements and get to cutting!

#4

You are supposed to braze cast iron if you want it done 100% done correct. I am doing this as a test really to see if i can hold a consistant boost from start to finish with the stock turbo. Which is a huge problem still after 20+ years of the car being on the market.

I will run this car hard, and if cracks or leaks occur because I used regular MIG and TIG welding, I will re-do it with brazing.As long as it works and hold boost consistantly, which i'm pretty sure it will.I'm also pretty sure nothing will happen because i welded it instead of brazing it.No way to know without testing though!

I will run this car hard, and if cracks or leaks occur because I used regular MIG and TIG welding, I will re-do it with brazing.As long as it works and hold boost consistantly, which i'm pretty sure it will.I'm also pretty sure nothing will happen because i welded it instead of brazing it.No way to know without testing though!

#5

You are supposed to braze cast iron if you want it done 100% done correct. I am doing this as a test really to see if i can hold a consistant boost from start to finish with the stock turbo. Which is a huge problem still after 20+ years of the car being on the market.

I will run this car hard, and if cracks or leaks occur because I used regular MIG and TIG welding, I will re-do it with brazing.As long as it works and hold boost consistantly, which i'm pretty sure it will.I'm also pretty sure nothing will happen because i welded it instead of brazing it.No way to know without testing though!

I will run this car hard, and if cracks or leaks occur because I used regular MIG and TIG welding, I will re-do it with brazing.As long as it works and hold boost consistantly, which i'm pretty sure it will.I'm also pretty sure nothing will happen because i welded it instead of brazing it.No way to know without testing though!

Not necessarily true. Cast iron can be welded effectively, but it takes special preparations. The part needs to be preheated, and for best results, it should be tig welded with a high nickel rod. It could also be stick welded after preheating, and there are rods available specifically for welding cast iron. Mig welding will generally be the least effective form of welding on cast iron.

Brazing wont hold at the temps this may see.

#9

I made a new downpipe to clear the wastegate a little better. Then I was like "man, all this piping for what". It dosnt really make the car any quieter. So I dropped the entire exhaust and just welded to muffler to where the downpipe would normally end. Barely any louder. And dropped even more weight off the car.

The car sounds much deeper and better to me. Others say the same thing that have seen it in person. I'm guessing the manifold porting added to the better sound at least a little. The car spools twice as fast and I can even here the turbo spooling through the exhaust now. Sounds dope... But what beats that easily, is the sound of the wastegate when that big bitch open up! lol... scream crazy. And best of all, It holds boost easily anywhere I want it to all the way to whatever RPM I feel like taking it to... dopeness.

Before this, I could go through 1st, 2nd, and 3rd gear with out barely breaking the tires loose on the street. Now there's no hope for the tires in 1st, same for second. And third the tires are still smoking. I even tried rolling at about 45mph and ease in on the throttle, still lights the tires up! And these are 255 wide tires.... So did this help? **** yeah, like you wouldnt believe...

Oh ,and by the way, I havnt tuned the Apex-i NEO at all. Nothing. All of this with ZERO tuning. Now that I have a wideband back and have a second o2 bung in the downpipe, I can actually tune the car. It's only getting better.

Pics of everything installed!

The car sounds much deeper and better to me. Others say the same thing that have seen it in person. I'm guessing the manifold porting added to the better sound at least a little. The car spools twice as fast and I can even here the turbo spooling through the exhaust now. Sounds dope... But what beats that easily, is the sound of the wastegate when that big bitch open up! lol... scream crazy. And best of all, It holds boost easily anywhere I want it to all the way to whatever RPM I feel like taking it to... dopeness.

Before this, I could go through 1st, 2nd, and 3rd gear with out barely breaking the tires loose on the street. Now there's no hope for the tires in 1st, same for second. And third the tires are still smoking. I even tried rolling at about 45mph and ease in on the throttle, still lights the tires up! And these are 255 wide tires.... So did this help? **** yeah, like you wouldnt believe...

Oh ,and by the way, I havnt tuned the Apex-i NEO at all. Nothing. All of this with ZERO tuning. Now that I have a wideband back and have a second o2 bung in the downpipe, I can actually tune the car. It's only getting better.

Pics of everything installed!

#10

Knightsports offered a back plate kit for I think both s4 and s5 that has external wastegate mount on it for those that want external gate without the fab work.. The other way to fix creep with the S5 is to mill a recess in the back plate so the flapper opens wider, it actually works pretty well even with the stiffer hks wastegate actuator.

Thread

Thread Starter

Forum

Replies

Last Post

Luke_Tech

RX-7 & RX-8 Parts For Sale & Wanted

5

08-27-2006 04:25 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)