Porting mistake?

#1

Hi all,

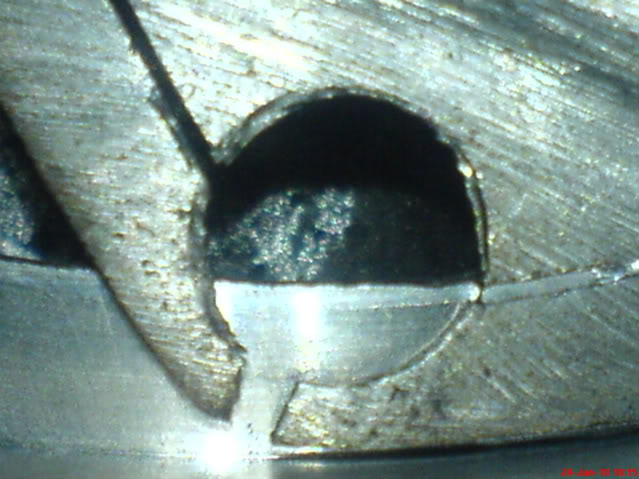

long time lurker, first time poster. Would like some feedback: have ported a little further than I would've liked on inlet opening towards the tail of the port on my 13b. The rest of the opening side above where the calliper is held is in the 11mm range, apart from the lower area as pictured. Will this cause me any problems or can I get away with using this plate? I understand the upper outer area/corner is more critical when removing metal and bevelling towards the closing edge but I don't want to run risk corner seal/ side seal failure on this one.

Many thanks in advance

long time lurker, first time poster. Would like some feedback: have ported a little further than I would've liked on inlet opening towards the tail of the port on my 13b. The rest of the opening side above where the calliper is held is in the 11mm range, apart from the lower area as pictured. Will this cause me any problems or can I get away with using this plate? I understand the upper outer area/corner is more critical when removing metal and bevelling towards the closing edge but I don't want to run risk corner seal/ side seal failure on this one.

Many thanks in advance

#2

Hi all,

long time lurker, first time poster. Would like some feedback: have ported a little further than I would've liked on inlet opening towards the tail of the port on my 13b. The rest of the opening side above where the calliper is held is in the 11mm range, apart from the lower area as pictured. Will this cause me any problems or can I get away with using this plate? I understand the upper outer area/corner is more critical when removing metal and bevelling towards the closing edge but I don't want to run risk corner seal/ side seal failure on this one.

Many thanks in advance

long time lurker, first time poster. Would like some feedback: have ported a little further than I would've liked on inlet opening towards the tail of the port on my 13b. The rest of the opening side above where the calliper is held is in the 11mm range, apart from the lower area as pictured. Will this cause me any problems or can I get away with using this plate? I understand the upper outer area/corner is more critical when removing metal and bevelling towards the closing edge but I don't want to run risk corner seal/ side seal failure on this one.

Many thanks in advance

So long as the leading end of the side seal is supported all the way across the port, there is no problem.

Look Here: https://www.nopistons.com/forums/Wha...12#entry921712

Lynn E. Hanover

#4

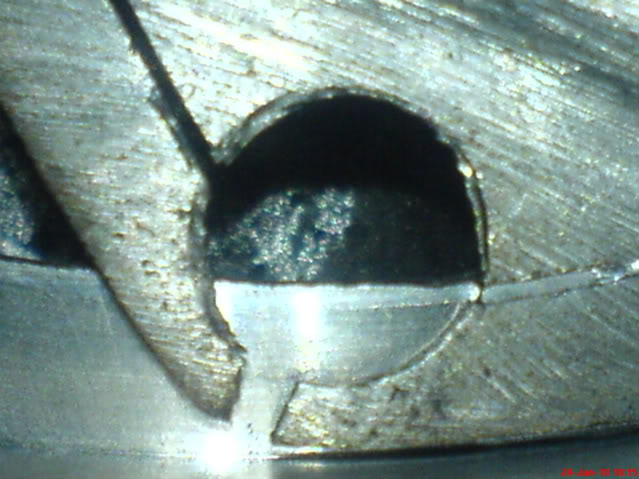

Finally got round to butchering an old damaged rotor and setting up the gear/shaft/housing assembly. The sideseal edge appears to ride on the very edge of the port, have taken a close up pic at the worst point. Have resigned myself that this plate is junk but if anyone feels otherwise please let me know:

#5

Finally got round to butchering an old damaged rotor and setting up the gear/shaft/housing assembly. The sideseal edge appears to ride on the very edge of the port, have taken a close up pic at the worst point. Have resigned myself that this plate is junk but if anyone feels otherwise please let me know:

Well look at that. You have the tool now that lets you look inside an engine to see what actually goes on.

This part of porting ia actually more forgiving than you would think.

Follow the leading end of the side seal around the port, and if it is supported, or at least the first inch is supported all along the port, it will be fine. I am guessing the rotor tip is moving from right to left in this picture. Now do the ramp trick at the closing line and notch the very bottom of the port so that the drooping trailing end will not be chipped when the engine turns backwards.

In the IMSA Racing Stocks days, no bridge ports were allowed, so folks made finger ports where the fingers of iron were left sticking out into the port to support the side and corner seal. So, there would be 4 or 5 edges for the seal to step over. Never a problem. 250 HP with a mdified Niki carb.

Lynn E. Hanover

#6

Thanks again Lynn, I stuck a side seal in there too and it looks like it just contacts metal as it goes around (although probably not an inch of leading sideseal?):

Have bevelled the closing edge and allowed for a scissoring action as the trailing seal passes over it; I might actually finish this plate in this case

Have bevelled the closing edge and allowed for a scissoring action as the trailing seal passes over it; I might actually finish this plate in this case

#7

Looks useable to me. I have done a couple that were ported at least as aggressive as yours. No problems with them. I just bevelled that closing edge and all is well so far. Good luck on your build.

Thread

Thread Starter

Forum

Replies

Last Post

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)