My porting pics with ito's street ports

#22

Originally Posted by oldone' post='912889' date='Dec 4 2008, 02:20 PM

All of the above that you have described I have experienced in my N\A race engines Lynn.I have even gone as far as to square the runners off by milling them,increasing the ports a fair bit.To be honest the result was only 184 horses on the wheels.I then opened the opening timing and closing timing on the ports and the power went down to 158 horses on the wheels.Low rpm driving just sucked.

However on experimenting on a 12a motor I cut a bigger bridge port on all plates,just cleaned up the runners and flowed some angles towards the ports,the lil motor feels so strong at 3000rpm and really gets on song at 5000rpm and pulls like a steam train from there onwards.Be interesting when I do some power runs on the dyno.

[attachment=45213 SCI0007.jpg]

SCI0007.jpg]

[attachment=45214 SCI0040.jpg]

SCI0040.jpg]

However on experimenting on a 12a motor I cut a bigger bridge port on all plates,just cleaned up the runners and flowed some angles towards the ports,the lil motor feels so strong at 3000rpm and really gets on song at 5000rpm and pulls like a steam train from there onwards.Be interesting when I do some power runs on the dyno.

[attachment=45213

SCI0007.jpg]

SCI0007.jpg][attachment=45214

SCI0040.jpg]

SCI0040.jpg]It seems that eventually everyone invents this port layout.

This used to be called the "Monster Port". It works well from 7,000 to 11,000 RPM, IF there is enough fuel and air available. Probably too much drag to work with a carb, no matter how big, but with a huge throttle body and injection, and not much below that.

It is still no match for even a home made Periphery Port engine. And a Periphery port engine does not improve if the side ports are left open. However, in a turbocharged engine for drag racing, you might have an effective engine.

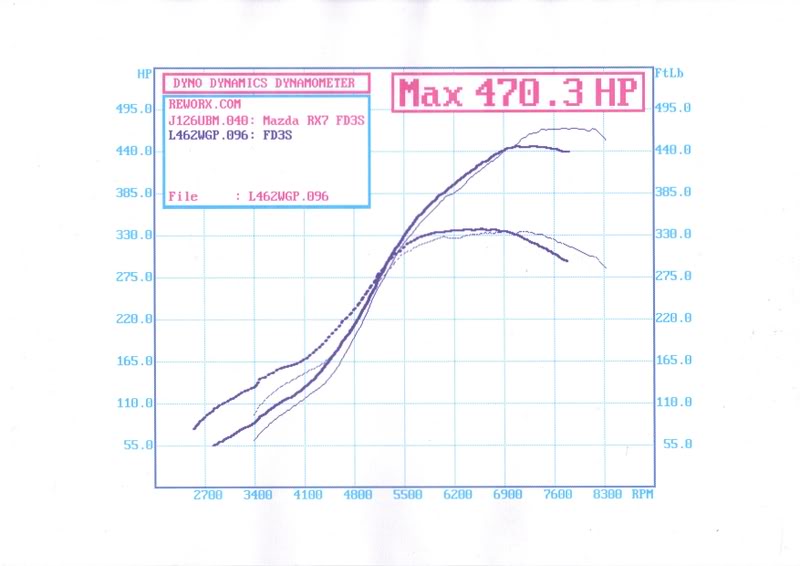

The Gold Standard for high power is still the Periphery port with a turbocharger. 500 HP per rotor or more. There was a Utube of a 1645HP three rotor on the dyno. You cannot cool that much HP, but you can drag race with it.

Lynn E. Hanover

#23

Originally Posted by Lynn E. Hanover' post='912963' date='Dec 6 2008, 03:18 PM

It seems that eventually everyone invents this port layout.

This used to be called the "Monster Port". It works well from 7,000 to 11,000 RPM, IF there is enough fuel and air available. Probably too much drag to work with a carb, no matter how big, but with a huge throttle body and injection, and not much below that.

It is still no match for even a home made Periphery Port engine. And a Periphery port engine does not improve if the side ports are left open. However, in a turbocharged engine for drag racing, you might have an effective engine.

The Gold Standard for high power is still the Periphery port with a turbocharger. 500 HP per rotor or more. There was a Utube of a 1645HP three rotor on the dyno. You cannot cool that much HP, but you can drag race with it.

Lynn E. Hanover

This used to be called the "Monster Port". It works well from 7,000 to 11,000 RPM, IF there is enough fuel and air available. Probably too much drag to work with a carb, no matter how big, but with a huge throttle body and injection, and not much below that.

It is still no match for even a home made Periphery Port engine. And a Periphery port engine does not improve if the side ports are left open. However, in a turbocharged engine for drag racing, you might have an effective engine.

The Gold Standard for high power is still the Periphery port with a turbocharger. 500 HP per rotor or more. There was a Utube of a 1645HP three rotor on the dyno. You cannot cool that much HP, but you can drag race with it.

Lynn E. Hanover

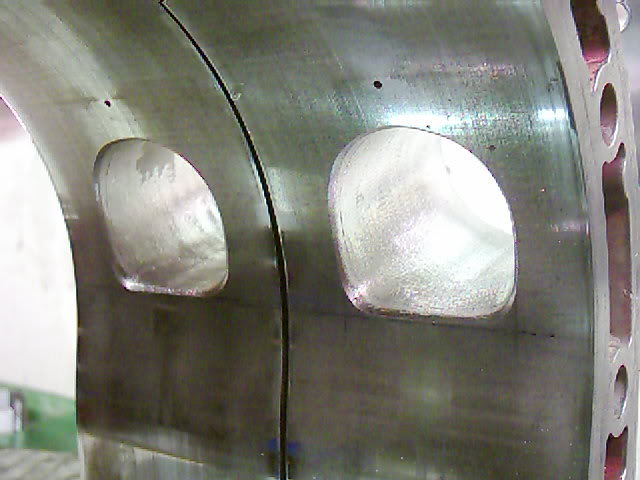

Know what you mean Lynn but I just love playing with some old school styles.Just love building all variants for my daily runner and enjoying them.The serious work is this:

Did this PP a few months ago yet to put it on the dyno:

#24

Originally Posted by oldone' post='912974' date='Dec 6 2008, 12:32 PM

Know what you mean Lynn but I just love playing with some old school styles.Just love building all variants for my daily runner and enjoying them.The serious work is this:

Did this PP a few months ago yet to put it on the dyno:

Did this PP a few months ago yet to put it on the dyno:

The bridgeports seem to add their help as really early opening. Once the flow through the main port is going well, not much comes through the bridge part of the port. So if you do a "J" port, you can open the port at say 110 degrees, and really get some help. The 10-32 screws are threded into the groove to block the seal ends. Along the remaining back rib of the groove wall, just add a bead of silicone, that also covers the screws. I never had a leak doing this, and it gives you about 250 HP from a Weber with 38MM chokes. But a big throttle body would get you past 270 HP as an NA engine. Practice on a junk iron.

#25

Originally Posted by diabolical1' post='909096' date='Oct 3 2008, 07:43 AM

if i may ...

i'll offer a few observations i've made as they apply to streetports. yes, many people do just go for the largest runner, latest closing port that they can cut. in a few cases, it's warranted and effective (depending on the person's actual understanding and the final setup of the engine), but in most cases it can hurt power where it counts. however, you can't convince many people that it's not helping - which it does ... at high RPM! but notice i said "where it counts" though, because on the street how often to you get to drive at high RPM outside of second gear? am i making sense?

you'll hear a lot of people say that RB's streetports are conservative, with the implication that conservative doesn't make good power. however, you may be surprised at how well a streetport based on RB's closing, a little more aggressive opening, some good contouring/blending in the bowl and simply removing the casting flash of the stock runner will perform.

that said, i actually believe RB's streetports are conservative - just without the implication that they are gutless. it's just that they are too small for my personal setups and how i drive.

so overall, i'm saying i think your observation/insight into what Lynn said is correct. at least, that's my take on it.

i'll offer a few observations i've made as they apply to streetports. yes, many people do just go for the largest runner, latest closing port that they can cut. in a few cases, it's warranted and effective (depending on the person's actual understanding and the final setup of the engine), but in most cases it can hurt power where it counts. however, you can't convince many people that it's not helping - which it does ... at high RPM! but notice i said "where it counts" though, because on the street how often to you get to drive at high RPM outside of second gear? am i making sense?

you'll hear a lot of people say that RB's streetports are conservative, with the implication that conservative doesn't make good power. however, you may be surprised at how well a streetport based on RB's closing, a little more aggressive opening, some good contouring/blending in the bowl and simply removing the casting flash of the stock runner will perform.

that said, i actually believe RB's streetports are conservative - just without the implication that they are gutless. it's just that they are too small for my personal setups and how i drive.

so overall, i'm saying i think your observation/insight into what Lynn said is correct. at least, that's my take on it.

+1. Err on the side of conservatism. Bigger is frequently not better and it's true in this case of porting.

B

#26

Here is a pic of a customers streetport I recently did, goal was power and torque in bottom end(daily driver, city driver). but quick acceleration. If you notice not a large port, but the closing transition is making up for the acceleration of the engine.. I did not make the port to large, but I payed close attention to the closing of the port.. Car has not been dynoed, but I could tell you, between 2500 to 6500 rpms car feels very responsive.. mission accomplished so far... Ports could be played with according to application, like lynn said you cannot have your cake and eat it too!!! if you gain a little in top end power, you loose a little in bottom end power.. really your understanding of your particular need before you start making a huge hole in the side housings..

#28

Originally Posted by Lynn E. Hanover' post='912903' date='Dec 5 2008, 04:25 AM

The main difference is that 14.7 pounds of boost of the NA or, Normally Aspirated engine has to work with. With a turbocharged or supercharged engine, you can force feed mixture at nearly any rate you might want. Now thw breathing will be limited by the strength of the engine, and your ability to remove the excess heat.

The engines are about 28% effiecient, so about 72% of the heat from burning fuel escapes as waste heat. Mostly through the exhaust heat and then some as oil heat and some through the water or coolant. So, less than 30% of the energy ingested is available to do anything with. There are some losses that are the same for piston, rotary and turbo rotary engines. Oil shearing, mechanical drag, and chamber shape losses.

So for every 10 gallons of fuel, you get to use 3 and 7 go down the drain. So there is still an opening for a more effiecent engine design, and even the use of ceramics and other material changes that can limit heat losses.

The turbocharger recovers a small amount of energy from the waste exhaust flow, to drive the compressor. In WWII the Wright (the company the Wright Brothers started) aeronautics company built a radial airplane engine that had dual stage superchargers, and three exhaust turbines that recovered energy from the exhaust flow and added that power back into the cam ring in that engine. This engine had 3,350 cubic inches of displacement. There was also a 4,360 cubic inch engine.

One method of dealing with the excess heat of the boosted engine is to just use it for s few seconds.

So the heat does not get high enough to damage the engine. The other problem is that you are chaning the compression ratio of the engine as you add boost pressure. The engine stays the same size but you double or triple the volume of mixture you force into it, so the actual compression ratio goes off the charts. So boosted engines might have an ignition advance of 5 degrees or less at full boogie, while a NA engine might have 25 degrees at that same load and RPM.

So, the NA engine is difficult to detonate, and the boosted engine is easy to detonate. So boosted engines have all kinds of things going on to prevent detonation, that are not required on an NA engine.

Since the velocity of the inlet tract is now a function of boost, the runner size is just as big as you can get it. If you want more velocity, you turn up the boost.

To keep the engine together you need an intercooler. Since detonation is a function of charge temperature, you do all kinds of things to keep that temp as low as is possible. You inject water. Latent heat of evaoporation cools the charge, and water slows the flame front so it mimics higher octane fuel.

You reduce ignition lead because the much higher compression, has the flame front moving very fast and chamber pressures are very high. The oil is cooler. The water is cooler. The location where air is collected for the engine to breath is cooler. Once compressed (heated) air is inside the car it is run through a cooler. (intercooler). Just to keep the engine alive.

So, there you are. Runner size is not reducing power, it is increasing it. The reverse of the NA engine.

Lynn E. Hanover

The engines are about 28% effiecient, so about 72% of the heat from burning fuel escapes as waste heat. Mostly through the exhaust heat and then some as oil heat and some through the water or coolant. So, less than 30% of the energy ingested is available to do anything with. There are some losses that are the same for piston, rotary and turbo rotary engines. Oil shearing, mechanical drag, and chamber shape losses.

So for every 10 gallons of fuel, you get to use 3 and 7 go down the drain. So there is still an opening for a more effiecent engine design, and even the use of ceramics and other material changes that can limit heat losses.

The turbocharger recovers a small amount of energy from the waste exhaust flow, to drive the compressor. In WWII the Wright (the company the Wright Brothers started) aeronautics company built a radial airplane engine that had dual stage superchargers, and three exhaust turbines that recovered energy from the exhaust flow and added that power back into the cam ring in that engine. This engine had 3,350 cubic inches of displacement. There was also a 4,360 cubic inch engine.

One method of dealing with the excess heat of the boosted engine is to just use it for s few seconds.

So the heat does not get high enough to damage the engine. The other problem is that you are chaning the compression ratio of the engine as you add boost pressure. The engine stays the same size but you double or triple the volume of mixture you force into it, so the actual compression ratio goes off the charts. So boosted engines might have an ignition advance of 5 degrees or less at full boogie, while a NA engine might have 25 degrees at that same load and RPM.

So, the NA engine is difficult to detonate, and the boosted engine is easy to detonate. So boosted engines have all kinds of things going on to prevent detonation, that are not required on an NA engine.

Since the velocity of the inlet tract is now a function of boost, the runner size is just as big as you can get it. If you want more velocity, you turn up the boost.

To keep the engine together you need an intercooler. Since detonation is a function of charge temperature, you do all kinds of things to keep that temp as low as is possible. You inject water. Latent heat of evaoporation cools the charge, and water slows the flame front so it mimics higher octane fuel.

You reduce ignition lead because the much higher compression, has the flame front moving very fast and chamber pressures are very high. The oil is cooler. The water is cooler. The location where air is collected for the engine to breath is cooler. Once compressed (heated) air is inside the car it is run through a cooler. (intercooler). Just to keep the engine alive.

So, there you are. Runner size is not reducing power, it is increasing it. The reverse of the NA engine.

Lynn E. Hanover

Also tasty work as always Oldone