Lets talk TURBO PP designs

#12

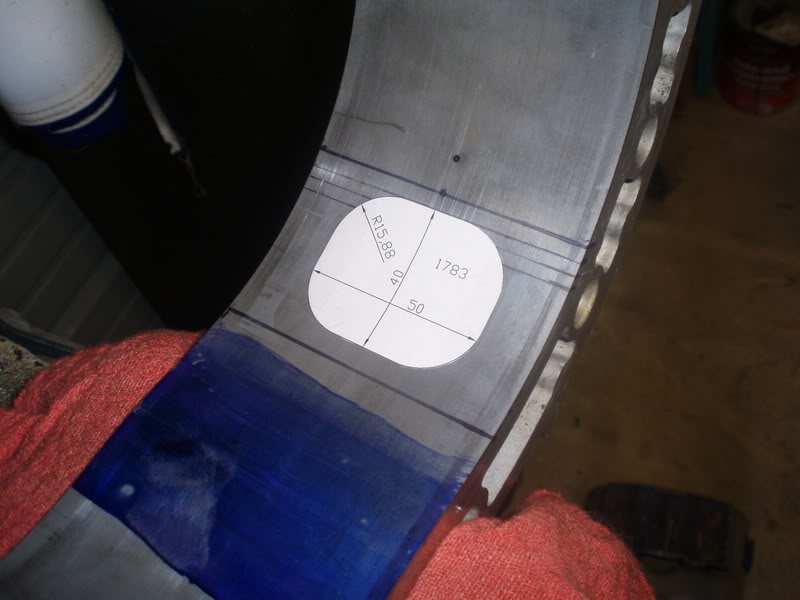

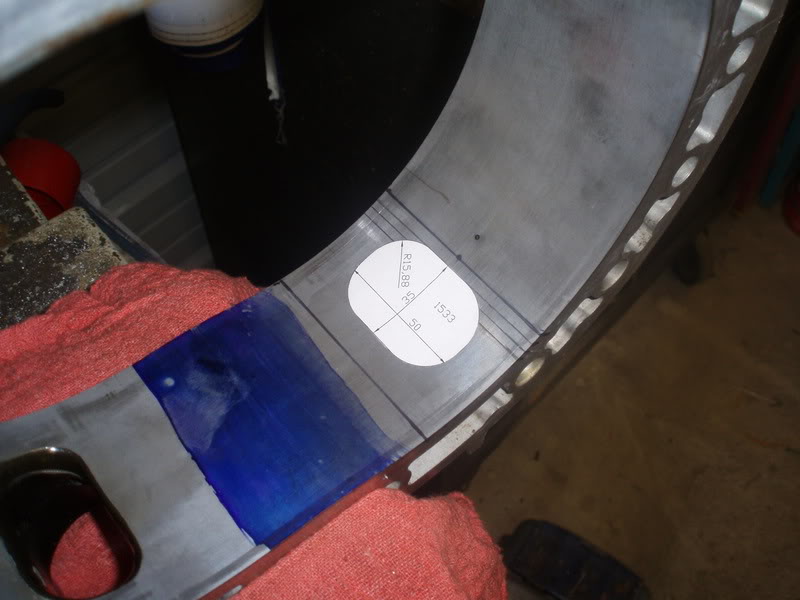

Did a bit of layout work to see how the port I was thinking of using would compare to the MFR port and to find out what the port timing would be.

The port I designed would close at the same time as the MFR port, but open 15 degrees later.

Finding port timing with degree wheel:

MFR port:

Square port I'm thinking about using:

The port I designed would close at the same time as the MFR port, but open 15 degrees later.

Finding port timing with degree wheel:

MFR port:

Square port I'm thinking about using:

#13

Your port will be peakier and higher revving than the MFR port. The timing is slightly less, but the area is greater. Squared off ports generally sacrifice low and mid range torque for peak hp numbers, and your slightly earlier timing will only hurt low end and midrange torque more. If you want a broad powerband with a decend low end, Id round out all of corners a lot more to make an oval out of your port. Earlier open will increase the midrange torque, and to a lesser extent bottom end torque, but it may make the engine less tolerant of low load operation. It will also bring the peak torque and peak power rpm down a bit.

Late closing ports reduce the dynamic compression at low rpm because the port is still open as the engine enters the compression stroke. At higher rpm, the inertia of the air column entering the engine can overcome this, and the increase in port timing will give a higher peak hp. But it will do so at the expense of low and mid rpm torque, therefore making the engine very peaky. I did a late close intake porting on a 6 port engine I had a while back. The torque peaked at 5500 rpm and was almost flat through 9000 rpm. It was a dog below 4000 rpm though. My 500 lb heavier all stock vert pulled harder below 4k rpm.

Late closing ports reduce the dynamic compression at low rpm because the port is still open as the engine enters the compression stroke. At higher rpm, the inertia of the air column entering the engine can overcome this, and the increase in port timing will give a higher peak hp. But it will do so at the expense of low and mid rpm torque, therefore making the engine very peaky. I did a late close intake porting on a 6 port engine I had a while back. The torque peaked at 5500 rpm and was almost flat through 9000 rpm. It was a dog below 4000 rpm though. My 500 lb heavier all stock vert pulled harder below 4k rpm.

#16

Originally Posted by C. Ludwig' post='892198' date='Jan 14 2008, 08:54 AM

Since you're going turbo have you thought of doing a semi-pp? It's the more proven of the options as far as turbo setups. That combined with the bridge port irons of your old engine?

I have, but I'm not going to have the time to build the complex intake manifold required. The PP manifold will be much easier to build and shouldn't take nearly as much time or money.

Any thoughts on runner entry angle?

#17

The RB pp's with the runner angled down into the port produced measurably less hp than the MFR ones with the port going straight into the housing. I believe both had the same timing and area. I dont remember specifics, it was a very long time ago when i read about it. Regardless, the port will flow better with the runner coming straight into the housing.

Since you are going turbo, Id cut back on the port timing and area as well. PP's flow very well. A 1.5" ID PP has been proven to make about 220 flywheel hp(n/a) in aircraft engines with fixed timing. It was rumored that Jesus Padilla's all motor 13b drag car was making 360 whp. The R26B with the MFR PP housings made 690 hp in endurance race trim, and Mazda stated the engine was capable of well over 700 hp. Even the 690 translates to 345 crank hp for a 2 rotor.

Since you are going turbo, Id cut back on the port timing and area as well. PP's flow very well. A 1.5" ID PP has been proven to make about 220 flywheel hp(n/a) in aircraft engines with fixed timing. It was rumored that Jesus Padilla's all motor 13b drag car was making 360 whp. The R26B with the MFR PP housings made 690 hp in endurance race trim, and Mazda stated the engine was capable of well over 700 hp. Even the 690 translates to 345 crank hp for a 2 rotor.

#19

Dont go too agressive. The more agressive you are with timing and area on the exhaust port, the more sensitive the engine is to backpressure. Id match it out to the exhaust sleeve, or maybe a little bigger. Something interesting is making a new exhaust sleeve with less, or no expansion ratio at all. It adds a considerably amount of velocity to the exhaust without reducing flow. I remember one guy in particular who went from a 1.00 a/r to a 1.32 with the zero expansion ratio sleeves, with no loss in boost response at all. The problem was so much heat and energy was added to the exhaust that it melted his turbine wheel in a matter of weeks. The problem was solved with an inconel turbine wheel, but they dont come cheap.

Thats a bit extreme for most people, so the general concensus for good streetable power is a rounded bottom edge down a few mm from stock, keep the squared off top, but raise it up a little, I usually a little higher than the stock bevel. Then basically match the rest to the steel exhaust sleeve. I do reshape it so the runner is at a bit of an angle, almost following the top of the sleeve. Its a little hard to explain, but when you look at it, and think about how the exhaust will be flowing through, its pretty easy to visualize. And be sure you add a bevel to the top edge of the exhaust port like stock, otherwise it will wear out the apex seal in a short period.

Heres a pic of a relatively mild exhaust port I did on an REW.

[attachment=43708 SCF0284.JPG]

SCF0284.JPG]

Thats a bit extreme for most people, so the general concensus for good streetable power is a rounded bottom edge down a few mm from stock, keep the squared off top, but raise it up a little, I usually a little higher than the stock bevel. Then basically match the rest to the steel exhaust sleeve. I do reshape it so the runner is at a bit of an angle, almost following the top of the sleeve. Its a little hard to explain, but when you look at it, and think about how the exhaust will be flowing through, its pretty easy to visualize. And be sure you add a bevel to the top edge of the exhaust port like stock, otherwise it will wear out the apex seal in a short period.

Heres a pic of a relatively mild exhaust port I did on an REW.

[attachment=43708

SCF0284.JPG]

SCF0284.JPG]

#20

I made a few variations of the port, which do you think would work best? Should I shift the port down even further? What would change between making the exhaust port squared on both the top and bottom vs rounded bottom and squared top?

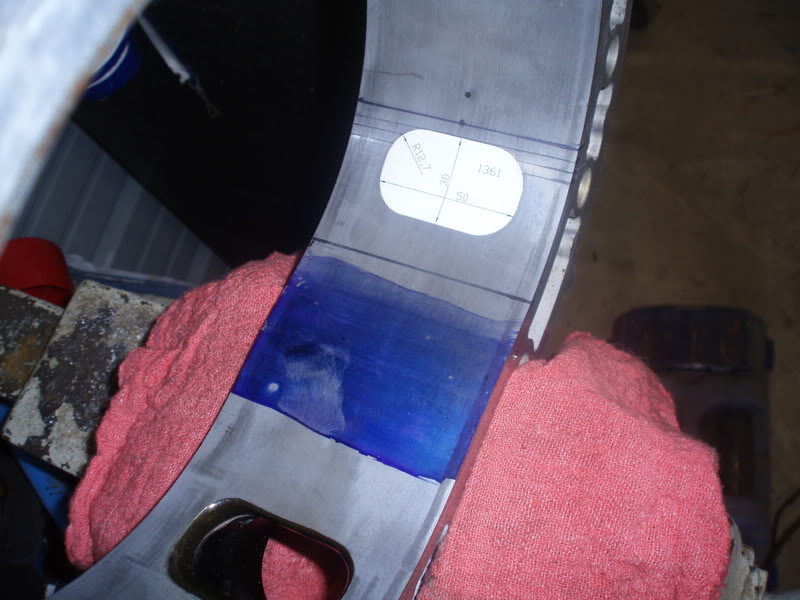

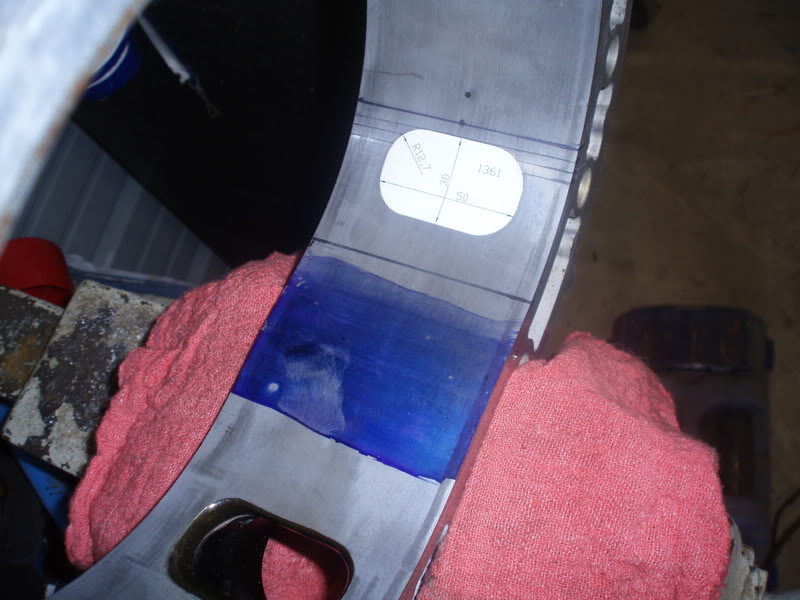

Nearly the same size as the previous port but with rounder corners; port moved down 5 degrees:

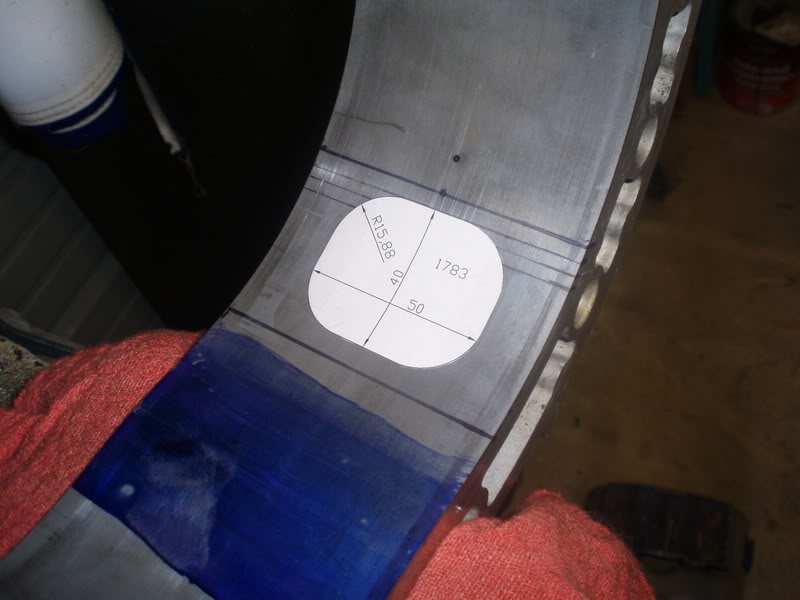

5mm shorter, same radius, also moved down 5 degrees:

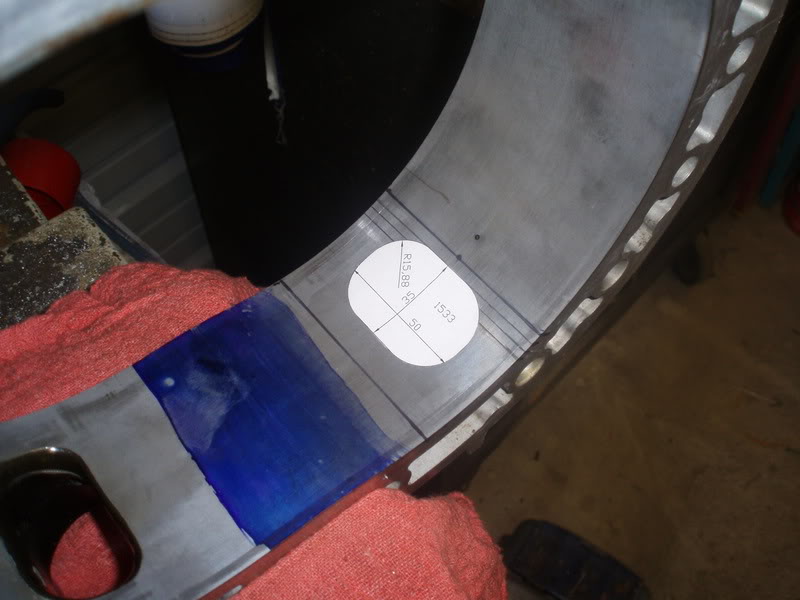

Another 5mm shorter, same 5 degree shift:

Nearly the same size as the previous port but with rounder corners; port moved down 5 degrees:

5mm shorter, same radius, also moved down 5 degrees:

Another 5mm shorter, same 5 degree shift: