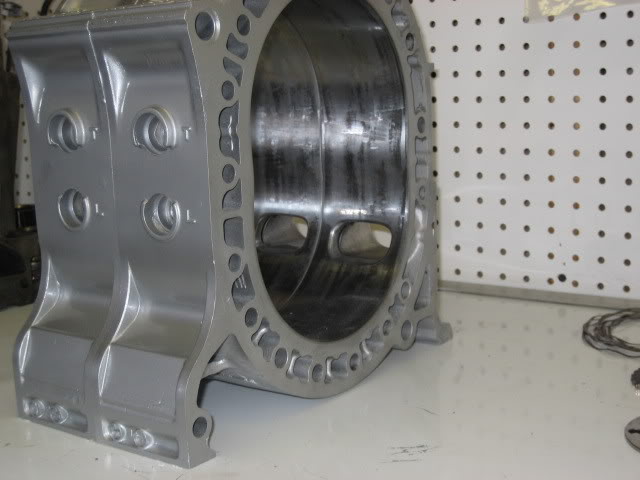

HBP and exhaust large port 4pt T motor

#11

I really like how clean your ports are, did you spend a good deal of time cleaning them up after you used the mill?

One question, when you did the eyebrow, did you do it in sections or in one tool path?

If you did it in one shot, I thought that the curve would require more speed and feed rate to get it smooth the way you did it.

Just curious.

I wish I had access to my Dad's garage down in AZ, he has all of the tools I wish I had the space for.

The next time I visit him I want to take a couple of scrap irons that I have laying around and practice.

Like I said before, nice work.

Anyone who can use a mill properly gets an A+ from me.

Erik

One question, when you did the eyebrow, did you do it in sections or in one tool path?

If you did it in one shot, I thought that the curve would require more speed and feed rate to get it smooth the way you did it.

Just curious.

I wish I had access to my Dad's garage down in AZ, he has all of the tools I wish I had the space for.

The next time I visit him I want to take a couple of scrap irons that I have laying around and practice.

Like I said before, nice work.

Anyone who can use a mill properly gets an A+ from me.

Erik

#12

Originally Posted by racerguy180' post='864771' date='Mar 22 2007, 12:20 AM

I really like how clean your ports are, did you spend a good deal of time cleaning them up after you used the mill?

One question, when you did the eyebrow, did you do it in sections or in one tool path?

If you did it in one shot, I thought that the curve would require more speed and feed rate to get it smooth the way you did it.

Just curious.

I wish I had access to my Dad's garage down in AZ, he has all of the tools I wish I had the space for.

The next time I visit him I want to take a couple of scrap irons that I have laying around and practice.

Like I said before, nice work.

Anyone who can use a mill properly gets an A+ from me.

Erik

I used a end mill bit and drilled down and then cranked the access wheels to cut the bridge. So yes I did it all in one time but no it is not a straight line it curves along the side seal track. Just takes allot of time cranking X and Y and together to get an arch. Keeping in mind not to fast so the bit don't brake.

#15

Originally Posted by iceblue' post='865477' date='Mar 26 2007, 05:49 PM

A milling machine is a form of a Lathe. The Lathe is the father of all machine tools. The milling machine is a lathe stood on end with the headstock on top.

If you add a 90 degree sine plate and an indexing table to the lathe, you have a horizontal mill.

And the same for a drill press. A lathe on end with the head stock on top. A heavy drill press works very well as a milling machine. With an indexing table and a good stiff drill press, you can regrind dog rings and gear dogs. A very good thing if you use a dog ring transmission.

Lynn E. Hanover

Picture is my Mazda powered CanAm car.

#20