First Attempt at Soldering. Suggestions Comments?

#11

Originally Posted by Rob x-7' post='850781' date='Dec 29 2006, 04:25 PM

does solder still have lead in it?

yeah i beleive it does. They have other alternatives that have the same electrical properties but without the hazard of working with lead.

Jason NYC

#15

Thanks for the compliments. Yeah butane is also portable which is an added plus.

Originally Posted by sidewinderx7' post='850852' date='Dec 30 2006, 08:47 AM

I bought this contraption and it works great!

That thing looks crazy, it could be a toture device!

Thanks for the feedback everyone

Jason NYC

NYRA Prez

www.nyrotary.com

#16

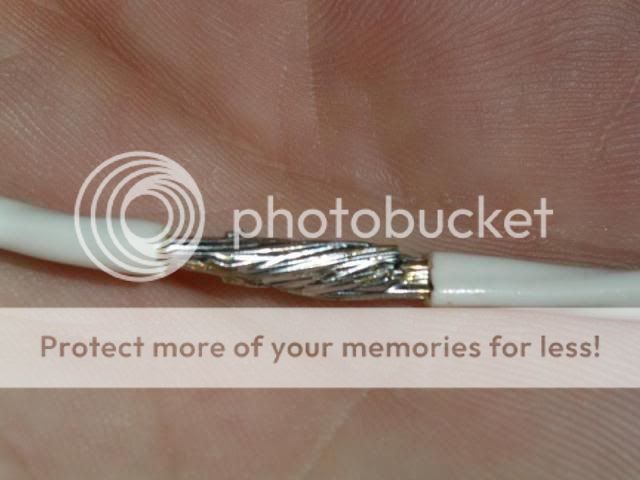

Heres another one that i just did. I did what my a friend of mines told me to do. I put the strands of the two wires into one another then twistied them.

Question: A bit of the cable under the insulation gets hards also, is it becuase the solder thats extra flows into the rest of the cable if it has been saturated enough?

I did a lil experiemtn and left the heat on for a bit longer and kept adding solder till the entire cable on both sides were hard like rocks. it looks dark grey/black after i peeled the insulation.

Im trying to find how long you should leave the soldering iron to the cable while applying solder. I know it also depends on gauge, the thicker the longer. Does anyone have a list of different gauges and how long heat should be applied. Or should i just practice with diff gauges when the times comes

More pics. 360 degrees of a peice i just did

^^ On this peice only a small portion of the cable under the insulation was hard. The rest remained flexible as it was prior to soldering. I assume this is the best, cuz you still need it to be workable.

Thanks

Jason

Question: A bit of the cable under the insulation gets hards also, is it becuase the solder thats extra flows into the rest of the cable if it has been saturated enough?

I did a lil experiemtn and left the heat on for a bit longer and kept adding solder till the entire cable on both sides were hard like rocks. it looks dark grey/black after i peeled the insulation.

Im trying to find how long you should leave the soldering iron to the cable while applying solder. I know it also depends on gauge, the thicker the longer. Does anyone have a list of different gauges and how long heat should be applied. Or should i just practice with diff gauges when the times comes

More pics. 360 degrees of a peice i just did

^^ On this peice only a small portion of the cable under the insulation was hard. The rest remained flexible as it was prior to soldering. I assume this is the best, cuz you still need it to be workable.

Thanks

Jason

#18

Originally Posted by ROTARYROCKET7' post='850914' date='Dec 30 2006, 07:56 PM

Heres another one that i just did. I did what my a friend of mines told me to do. I put the strands of the two wires into one another then twistied them.

Question: A bit of the cable under the insulation gets hards also, is it becuase the solder thats extra flows into the rest of the cable if it has been saturated enough?

I did a lil experiemtn and left the heat on for a bit longer and kept adding solder till the entire cable on both sides were hard like rocks. it looks dark grey/black after i peeled the insulation.

Im trying to find how long you should leave the soldering iron to the cable while applying solder. I know it also depends on gauge, the thicker the longer. Does anyone have a list of different gauges and how long heat should be applied. Or should i just practice with diff gauges when the times comes

More pics. 360 degrees of a peice i just did

^^ On this peice only a small portion of the cable under the insulation was hard. The rest remained flexible as it was prior to soldering. I assume this is the best, cuz you still need it to be workable.

Thanks

Jason

james nj

#19

THANKS guys i really find it fun to solder lloll, i been soldering a whole bunch of stuff.

Im going to crack open this old computer and start doing PCB's with my 25 watt ,700F 1/8" soldering pen =)

Im going to crack open this old computer and start doing PCB's with my 25 watt ,700F 1/8" soldering pen =)