13B MFR side plate and rotary housing wear

#1

Hi all.

I have a project putting together a 13B MFR engine (Mazda Factory Racing). Please have a look at the photos and share your knowedge. I would really appreciate your input on this. I also posted this on the rx7club forum(more photos): Rx7club post

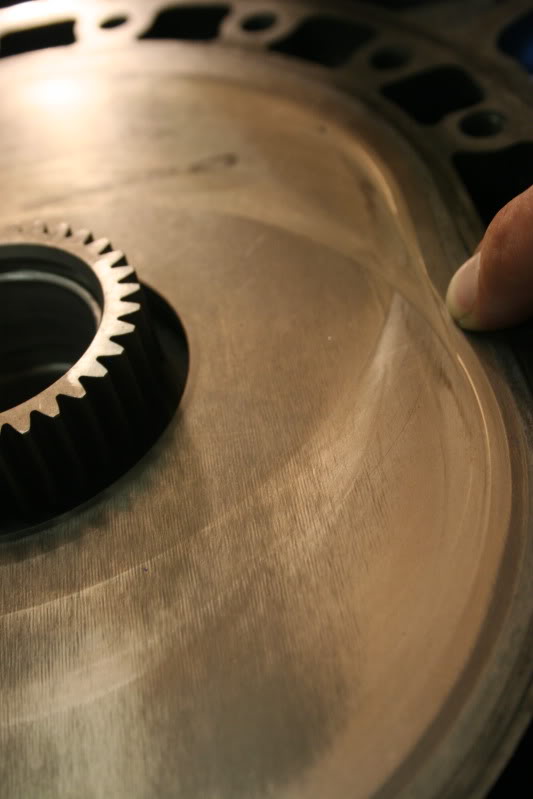

There is excessive wear in the side plates on this engine.

The engine did run for a few hours on the track after the sideplates were lapped and treated.

Please have a look at the photos and zoom in for details. They are both of the same plate, but all the plates are equal. It looks like a crack, but I cant really determine this. It might also be wear, but I feel the wear pattern is a bit strange? What are your thoughts?

2 engine builders have looked at this, and one is determined it is bechause of sand entering the engine causing them to wear. The other is claiming that the side plate hardening that is insufficient and this is causing the increase in wear. (Nitride treatment)

Is the nitride treatment anything for wear/hardness, or is it just for anti corrosion?

I have an intermidiate plate from a 12A (brand new). Can I use this plate on the MFR? (They look very similar).

What is the best stuff to fill the side port with (they are not in use since this is a Peripheral port engine)?

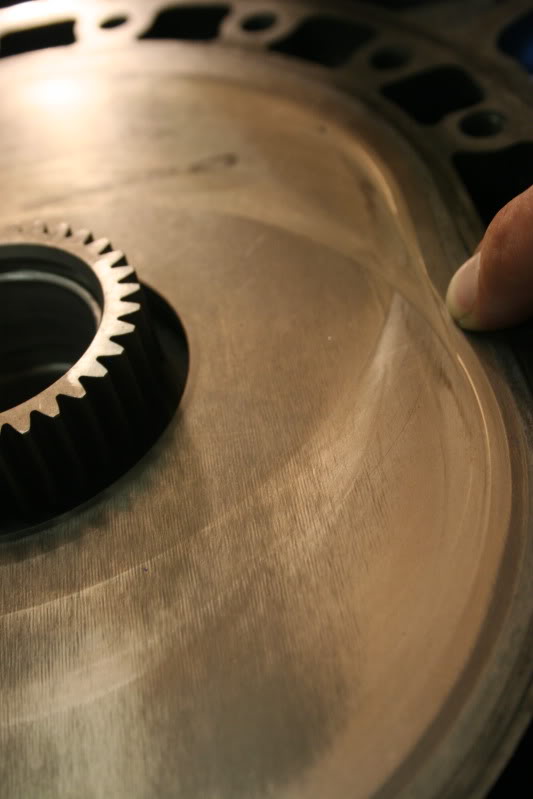

Here are a few photos of the surface of the rotorhousing. The photos are not that good. I took them with my cellphone trough the inlet port.

Looking at the photos, is it possible to judge:

1. No or little sand has entered the engine?

2. The small, but many, cracks in the surface are normal, and has no practical influence on the durability and performance of the engine. (I was told that this is the nature of housings without steel inserts).

(the photos are all of the same housing. The other housing look exactly the same)

[/QUOTE]

[/QUOTE]

The engine is out of this car: http://mohlin.wankeltrim.se/viewpage.php?page_id=2[/

I have a project putting together a 13B MFR engine (Mazda Factory Racing). Please have a look at the photos and share your knowedge. I would really appreciate your input on this. I also posted this on the rx7club forum(more photos): Rx7club post

There is excessive wear in the side plates on this engine.

The engine did run for a few hours on the track after the sideplates were lapped and treated.

Please have a look at the photos and zoom in for details. They are both of the same plate, but all the plates are equal. It looks like a crack, but I cant really determine this. It might also be wear, but I feel the wear pattern is a bit strange? What are your thoughts?

2 engine builders have looked at this, and one is determined it is bechause of sand entering the engine causing them to wear. The other is claiming that the side plate hardening that is insufficient and this is causing the increase in wear. (Nitride treatment)

Is the nitride treatment anything for wear/hardness, or is it just for anti corrosion?

I have an intermidiate plate from a 12A (brand new). Can I use this plate on the MFR? (They look very similar).

What is the best stuff to fill the side port with (they are not in use since this is a Peripheral port engine)?

Here are a few photos of the surface of the rotorhousing. The photos are not that good. I took them with my cellphone trough the inlet port.

Looking at the photos, is it possible to judge:

1. No or little sand has entered the engine?

2. The small, but many, cracks in the surface are normal, and has no practical influence on the durability and performance of the engine. (I was told that this is the nature of housings without steel inserts).

(the photos are all of the same housing. The other housing look exactly the same)

[/QUOTE]

[/QUOTE]The engine is out of this car: http://mohlin.wankeltrim.se/viewpage.php?page_id=2[/

#2

Hi all.

I have a project putting together a 13B MFR engine (Mazda Factory Racing). Please have a look at the photos and share your knowedge. I would really appreciate your input on this. I also posted this on the rx7club forum(more photos): Rx7club post

There is excessive wear in the side plates on this engine.

The engine did run for a few hours on the track after the sideplates were lapped and treated.

Please have a look at the photos and zoom in for details. They are both of the same plate, but all the plates are equal. It looks like a crack, but I cant really determine this. It might also be wear, but I feel the wear pattern is a bit strange? What are your thoughts?

2 engine builders have looked at this, and one is determined it is bechause of sand entering the engine causing them to wear. The other is claiming that the side plate hardening that is insufficient and this is causing the increase in wear. (Nitride treatment)

Is the nitride treatment anything for wear/hardness, or is it just for anti corrosion?

I have an intermidiate plate from a 12A (brand new). Can I use this plate on the MFR? (They look very similar).

What is the best stuff to fill the side port with (they are not in use since this is a Peripheral port engine)?

Here are a few photos of the surface of the rotorhousing. The photos are not that good. I took them with my cellphone trough the inlet port.

Looking at the photos, is it possible to judge:

1. No or little sand has entered the engine?

2. The small, but many, cracks in the surface are normal, and has no practical influence on the durability and performance of the engine. (I was told that this is the nature of housings without steel inserts).

I have a project putting together a 13B MFR engine (Mazda Factory Racing). Please have a look at the photos and share your knowedge. I would really appreciate your input on this. I also posted this on the rx7club forum(more photos): Rx7club post

There is excessive wear in the side plates on this engine.

The engine did run for a few hours on the track after the sideplates were lapped and treated.

Please have a look at the photos and zoom in for details. They are both of the same plate, but all the plates are equal. It looks like a crack, but I cant really determine this. It might also be wear, but I feel the wear pattern is a bit strange? What are your thoughts?

2 engine builders have looked at this, and one is determined it is bechause of sand entering the engine causing them to wear. The other is claiming that the side plate hardening that is insufficient and this is causing the increase in wear. (Nitride treatment)

Is the nitride treatment anything for wear/hardness, or is it just for anti corrosion?

I have an intermidiate plate from a 12A (brand new). Can I use this plate on the MFR? (They look very similar).

What is the best stuff to fill the side port with (they are not in use since this is a Peripheral port engine)?

Here are a few photos of the surface of the rotorhousing. The photos are not that good. I took them with my cellphone trough the inlet port.

Looking at the photos, is it possible to judge:

1. No or little sand has entered the engine?

2. The small, but many, cracks in the surface are normal, and has no practical influence on the durability and performance of the engine. (I was told that this is the nature of housings without steel inserts).

The iron has normal wear for about 70 thousand miles. The step from original surface to the worn surface can be up to .004" and be used as is. Above that a bit of compression will be lost when the new side seal corner wears to fit the rounded wear groove. Looks like not enough oil. Better to premix a bit of 2 cycle oil in each tank full.

You can have the plate(s) ground and lapped and re-nitrided. Or if the wear is minimal, lap this plate against the center iron to get a good oil holding finish and a more uniform surface. The wear pattern is normal, and shows you the track of the side seals.

Keep the rotor housing, and cut out the area beside the intake ports, so you can lay out primary ports in future engines.

Nitriding hardens the surface for better wear. Nitride is from one to two thousandths deep.

Lynn E. Hanover

#3

The rotor housing is unservicable. The lining has cracked.

The iron has normal wear for about 70 thousand miles. The step from original surface to the worn surface can be up to .004" and be used as is. Above that a bit of compression will be lost when the new side seal corner wears to fit the rounded wear groove. Looks like not enough oil. Better to premix a bit of 2 cycle oil in each tank full.

You can have the plate(s) ground and lapped and re-nitrided. Or if the wear is minimal, lap this plate against the center iron to get a good oil holding finish and a more uniform surface. The wear pattern is normal, and shows you the track of the side seals.

Keep the rotor housing, and cut out the area beside the intake ports, so you can lay out primary ports in future engines.

Nitriding hardens the surface for better wear. Nitride is from one to two thousandths deep.

Lynn E. Hanover

The iron has normal wear for about 70 thousand miles. The step from original surface to the worn surface can be up to .004" and be used as is. Above that a bit of compression will be lost when the new side seal corner wears to fit the rounded wear groove. Looks like not enough oil. Better to premix a bit of 2 cycle oil in each tank full.

You can have the plate(s) ground and lapped and re-nitrided. Or if the wear is minimal, lap this plate against the center iron to get a good oil holding finish and a more uniform surface. The wear pattern is normal, and shows you the track of the side seals.

Keep the rotor housing, and cut out the area beside the intake ports, so you can lay out primary ports in future engines.

Nitriding hardens the surface for better wear. Nitride is from one to two thousandths deep.

Lynn E. Hanover

Hi Lynn.

Thank you for your very quick feedback.

Is there any way to test the hardness of the nitride coating to prove that it was insufficient? Or if it was run without enough (or any) premix?

Do you recomend using the rotary housings, or is crome chipping at this stage "imminent", and trying to get more service/time out of this engine a waste of time/money?

I was recomended to put it here, and especially you to give your opinion. I am very greatful for your information.

Regards

#4

Hi Lynn.

Thank you for your very quick feedback.

Is there any way to test the hardness of the nitride coating to prove that it was insufficient? Or if it was run without enough (or any) premix?

Do you recomend using the rotary housings, or is crome chipping at this stage "imminent", and trying to get more service/time out of this engine a waste of time/money?

I was recomended to put it here, and especially you to give your opinion. I am very greatful for your information.

Regards

Thank you for your very quick feedback.

Is there any way to test the hardness of the nitride coating to prove that it was insufficient? Or if it was run without enough (or any) premix?

Do you recomend using the rotary housings, or is crome chipping at this stage "imminent", and trying to get more service/time out of this engine a waste of time/money?

I was recomended to put it here, and especially you to give your opinion. I am very greatful for your information.

Regards

The presence of nitride-forming elements (V, N, Nb) in the solid solution increases the strength of iron (10–12 kgf/mm2) but hardly changes or leads to a slight increase of the ductile-brittle temperature. Precipitation of nitrides during aging induces somewhat greater hardening (by 13–14 kgf/mm2) but leads to a sharp rise of the ductile-brittle temperature (by 150–200°). In alloys with a ferritic-pearlitic structure the hardening effect is larger (as much as 30–40 kgf/mm2) due to precipitation of nitrides in the process of decomposition of austenite and grain refining; the ductile-brittle temperature of alloys hardened with nitrides is somewhat higher (by 20–30° for unalloyed) or lower (by 20–30° for alloyed) for alloys without nitrides.

The hardening effect due to precipitation of nitrides during aging is negligible (5–7 kgf/mm2) for alloys with a structure of temper martensite, but the ductile—brittle temperature is lower (by 20–30°) despite the hardening.

I. P. Bardin Central Scientific-Research Institute of Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 5–10, January, 1980.

There you go.....

Nitrideing in all forms makes irons just a bit harder, but improves wear resistance at higher temperatures. As you know, wear is a function of mechanical machining in similar metals. Cast iron side seals running on a cast iron side housing (like cast iron piston rings in a cast iron piston engine bore) is a bad idea. Because similar metals sort of know each other, and don't mind blending at high temperatures. Thus the need to keep metals appart with a film of oil.

The more dissimilar the materials the better the wear in all cases. Even if one of the materials is not even a metal. Typically the further appart the materials on the Rockwell hardness scale the better the wear will be. Since the oil film keeps the pieces from touching, there should be no wear at all.

So, wear is evidence that an adequate oil film has been missing. You may have heard that most wear occures at start-up. And this is the case. How could this be. I change my oil on schedule?

An oil film can drain off because you shut off the engine while it is hot and oil flows freely when hot. So the cranking and first few seconds of operation is without a fully developed oil film on most surfaces. If the car is left to sit for long periods between uses, even worse. The poor distribution of oil pumped by the oil metering pump, favors the apex seals not the side seals. So you see the wear patterns in your pictures.

Note also that the same wear pattern appears on both sides of the iron, but the hot side wear is greater than the cold side. Hot iron wears faster than cold iron.

The difference in hardness may be difficult to determin as it may be slight. Check with a heat treat shop on this one. Also a Rockwell machine will press a diamond point into the surface being tested and will leave a pit or a dent with raised edges. So test in the BDC intake stroke area and be sure to smooth off the test dimple when finished.

With just a bit of premix, a rotary in normal operation should do 200,000 miles.

Other items of interst might be:

A device that fits between the OMP and the front case is available that allows the use of an ash free clean burning 2 cycle oil in the OMP. I would add a dash as premix as well. This gizmo then allows you to use a tru synthetic oil in the sump.

Also you might know that racing oils (both dyno and synthetics) have higher concentrations of Zinc anti wear compounds than do street oils. Also used in aircraft engine oils to prevent cam lobe wiping on start-up after a long drain down period. Sound helpfull?

The picture is a 3 rotor used as an aircraft engine.

Lynn E. Hanover

#6

That is a nice looking car. Is it a road racer? Turbocharged?

I have seen this failure mode in factory Pport housings, where a crossfire has occurred. So a chamber is closing on a fully burned charge, and the housing is flexing away from the rotor face. Very shinny bearings might also be found opposite the spark plug side. Notice the grainy look to the chrome where it looks like stepping stones with spaces in between. Caused by flexing. Might need lower boost. Might be detonating.

If just overheated, usually there is a horizontal crack through the trailing plug hole. There is a groove along one edge left by a corner seal end piece, and chrome flaking caused by the housing moving in and out. You can reduce the chrome along the edge of the housing about .001" with a diamond file to keep the chrome from flaking. If the housing shows signs of moving in the plugs area you might consider dowling the housing, going to zero clearance case bolts, and, or going to 32 pounds on the case bolts (dry threads).

Lynn E. Hanover

#7

That is a nice looking car. Is it a road racer? Turbocharged?

I have seen this failure mode in factory Pport housings, where a crossfire has occurred. So a chamber is closing on a fully burned charge, and the housing is flexing away from the rotor face. Very shinny bearings might also be found opposite the spark plug side. Notice the grainy look to the chrome where it looks like stepping stones with spaces in between. Caused by flexing. Might need lower boost. Might be detonating.

If just overheated, usually there is a horizontal crack through the trailing plug hole. There is a groove along one edge left by a corner seal end piece, and chrome flaking caused by the housing moving in and out. You can reduce the chrome along the edge of the housing about .001" with a diamond file to keep the chrome from flaking. If the housing shows signs of moving in the plugs area you might consider dowling the housing, going to zero clearance case bolts, and, or going to 32 pounds on the case bolts (dry threads).

Lynn E. Hanover

I have seen this failure mode in factory Pport housings, where a crossfire has occurred. So a chamber is closing on a fully burned charge, and the housing is flexing away from the rotor face. Very shinny bearings might also be found opposite the spark plug side. Notice the grainy look to the chrome where it looks like stepping stones with spaces in between. Caused by flexing. Might need lower boost. Might be detonating.

If just overheated, usually there is a horizontal crack through the trailing plug hole. There is a groove along one edge left by a corner seal end piece, and chrome flaking caused by the housing moving in and out. You can reduce the chrome along the edge of the housing about .001" with a diamond file to keep the chrome from flaking. If the housing shows signs of moving in the plugs area you might consider dowling the housing, going to zero clearance case bolts, and, or going to 32 pounds on the case bolts (dry threads).

Lynn E. Hanover

Thank you Lynn for some VERY good information.

The car is a trackcar running in the GT series. It is NA running a Kugelfisher injection. Here is a video: Race

I would highly appreciate if you could inform me if there is any more service left in the housings at this stage. If the crome is going rather quickly, I will get new housings, but if they can live another season, that is great. New housings are quite expensive you know.

Btw; were is a good source for these housings(new)? These obsolete castings seemes hard to come by. Is there anyone who makes a MFR housings with the more modern steel inserts?

Thank you again.

Frank Ove

#8

Thank you Lynn for some VERY good information.

The car is a trackcar running in the GT series. It is NA running a Kugelfisher injection. Here is a video: Race

I would highly appreciate if you could inform me if there is any more service left in the housings at this stage. If the crome is going rather quickly, I will get new housings, but if they can live another season, that is great. New housings are quite expensive you know.

Btw; where is a good source for these housings(new)? These obsolete castings seemes hard to come by. Is there anyone who makes a MFR housings with the more modern steel inserts?

Thank you again.

Frank Ove

The car is a trackcar running in the GT series. It is NA running a Kugelfisher injection. Here is a video: Race

I would highly appreciate if you could inform me if there is any more service left in the housings at this stage. If the crome is going rather quickly, I will get new housings, but if they can live another season, that is great. New housings are quite expensive you know.

Btw; where is a good source for these housings(new)? These obsolete castings seemes hard to come by. Is there anyone who makes a MFR housings with the more modern steel inserts?

Thank you again.

Frank Ove

The one with the crack (or looks like a crack, I would not use. Used housings in good condition can be reground and be as good as new. Damaged housings can have the chrome ground off and be rechromed, to be the same as new.

Here are some links I just got by typing in "used Mazda rotor housings" into the Google search engine.

http://jhbperformance.com/services.php

http://www.nrsrotorsports.com/

http://www.mazdatrix.com/

http://www.racingbeat.com/

http://www.rxforyour7.com/Rotary%20engines.htm

http://www.atkinsrotary.com/index.php?pag=0

http://www.shaneracing.com/index.html

http://www.rxforyour7.com/Rotary%20Engine.htm

http://dfwrotary.com/index.htm

http://www.xtremerotaries.com/index.php

http://www.rotaryengine.com/products/apexseals.htm

http://www.hurleyrotary.com/

If you sign up for the Mazda competition program you can buy parts direct from Mazda at dealer prices.

It takes color picture of both sides of the car, and lists of racing results.

Lynn E. Hanover

#9

[quote name='Lynn E. Hanover' timestamp='1284737106' post='935861']

The one with the crack (or looks like a crack, I would not use. If that is all you have available, you might try this.

Heat the cracked are a few seconds with a propane torch, and watch to see if any amount of oil comes out of the crack.

If the crack just gets wet but nothing flows out then the crack is just that and the iron below is still attached to the housing. If a bit of oil runs out, then that oil was contained in a void. Most likely between the iron liner and the rotor housing, and the housing is junk. The one picture without the crack has chatter marks where the apex seal has skipped along on the surface. Generally when seen above the trailing plug hole you might find too much timing advance, or some detonation, or too much timing split, or too much side clearance in the apex seal groove, or the apex seal springs have died, or not enough oil in the premix, or the premix oil is not ash free (clean burning).

Failing spring chatter marks ar more typical below the hump between the spark plugs. Stock or any steel like apex seals really don't like being reved very high. They are heavy and will not track the housing chrome at high velocity.

Carbon or ceramics are needed for over 9,000 RPM. A ceramic seal with 2 springs wll track to any known RPM.

What do you shift at now. How much HP do you have? What apex seals are you using. You know that except for the "O" ring grooves nearly any year rotor housings can be assembled into any engines. There may be slight differences in exhaust port shapes, but you would be changing that any way. If you make your own Periphery ports, you have a wide range of housing years to choose from. Even some nasty looking ones can be ground down, rechromed and returned to service. The same thing for irons. You can even use 12A irons, since you will be filling the ports with Epoxy anyway. Many of the Hyperlinks I posted lead to builders who sell good used housings. What engine is in the black car? Is he in your class?

Picture is my car.

Lynn E. Hanover

The one with the crack (or looks like a crack, I would not use. If that is all you have available, you might try this.

Heat the cracked are a few seconds with a propane torch, and watch to see if any amount of oil comes out of the crack.

If the crack just gets wet but nothing flows out then the crack is just that and the iron below is still attached to the housing. If a bit of oil runs out, then that oil was contained in a void. Most likely between the iron liner and the rotor housing, and the housing is junk. The one picture without the crack has chatter marks where the apex seal has skipped along on the surface. Generally when seen above the trailing plug hole you might find too much timing advance, or some detonation, or too much timing split, or too much side clearance in the apex seal groove, or the apex seal springs have died, or not enough oil in the premix, or the premix oil is not ash free (clean burning).

Failing spring chatter marks ar more typical below the hump between the spark plugs. Stock or any steel like apex seals really don't like being reved very high. They are heavy and will not track the housing chrome at high velocity.

Carbon or ceramics are needed for over 9,000 RPM. A ceramic seal with 2 springs wll track to any known RPM.

What do you shift at now. How much HP do you have? What apex seals are you using. You know that except for the "O" ring grooves nearly any year rotor housings can be assembled into any engines. There may be slight differences in exhaust port shapes, but you would be changing that any way. If you make your own Periphery ports, you have a wide range of housing years to choose from. Even some nasty looking ones can be ground down, rechromed and returned to service. The same thing for irons. You can even use 12A irons, since you will be filling the ports with Epoxy anyway. Many of the Hyperlinks I posted lead to builders who sell good used housings. What engine is in the black car? Is he in your class?

Picture is my car.

Lynn E. Hanover

Thread

Thread Starter

Forum

Replies

Last Post

mazdafun

Rotary Engine Building, Porting & Swaps

4

09-28-2010 07:02 PM

iox106

RX-7 & RX-8 Parts For Sale & Wanted

0

09-18-2007 07:44 PM

mike_rudy

RX-7 & RX-8 Parts For Sale & Wanted

1

12-15-2006 09:08 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)